Development Timeline and Milestones

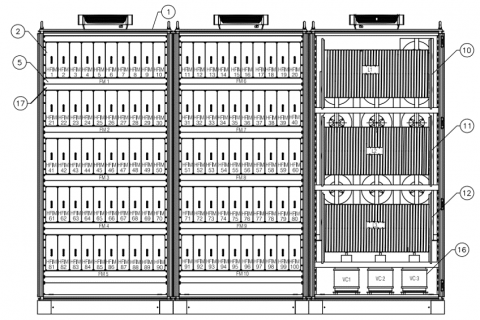

Installed Power supplies

Progressive RF Development Program

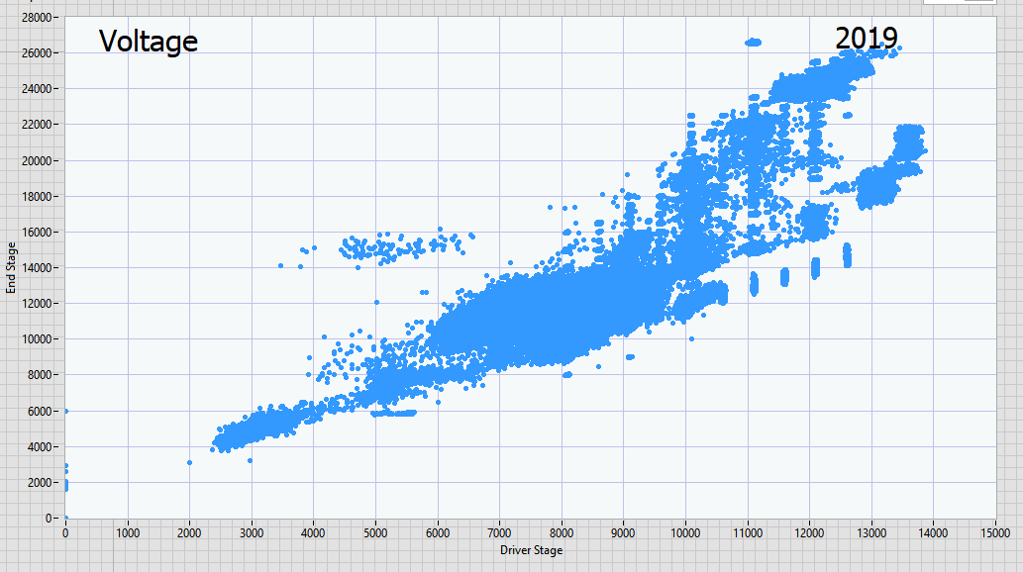

Systematic solid-state RF generator development: 5kW (2016) → 40kW (2018) → 200kW (under development) for plasma source applications, demonstrating scalable technology advancement.

Solid state RF generator - Phase wise development

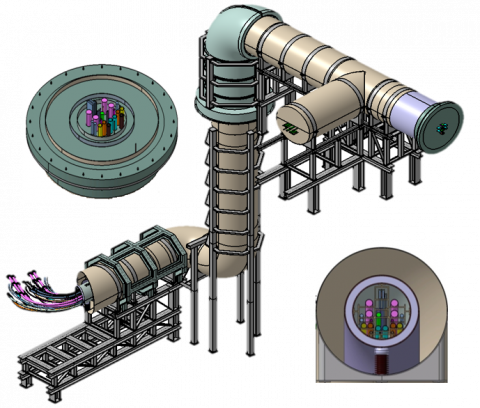

Transmission Line

HV Deck

Operations

- Successful demonstration with CEC and Thales make ICRF sources for 3600s and beyond.

- Extensive Operations with IC, EC, LHCD sources at II lab/IPR

- Successful demonstration with 1MW Gyrotron for 1000s repetitive shots.

- Continuous operations

Issues – resolutions – improvements – continuous interactions

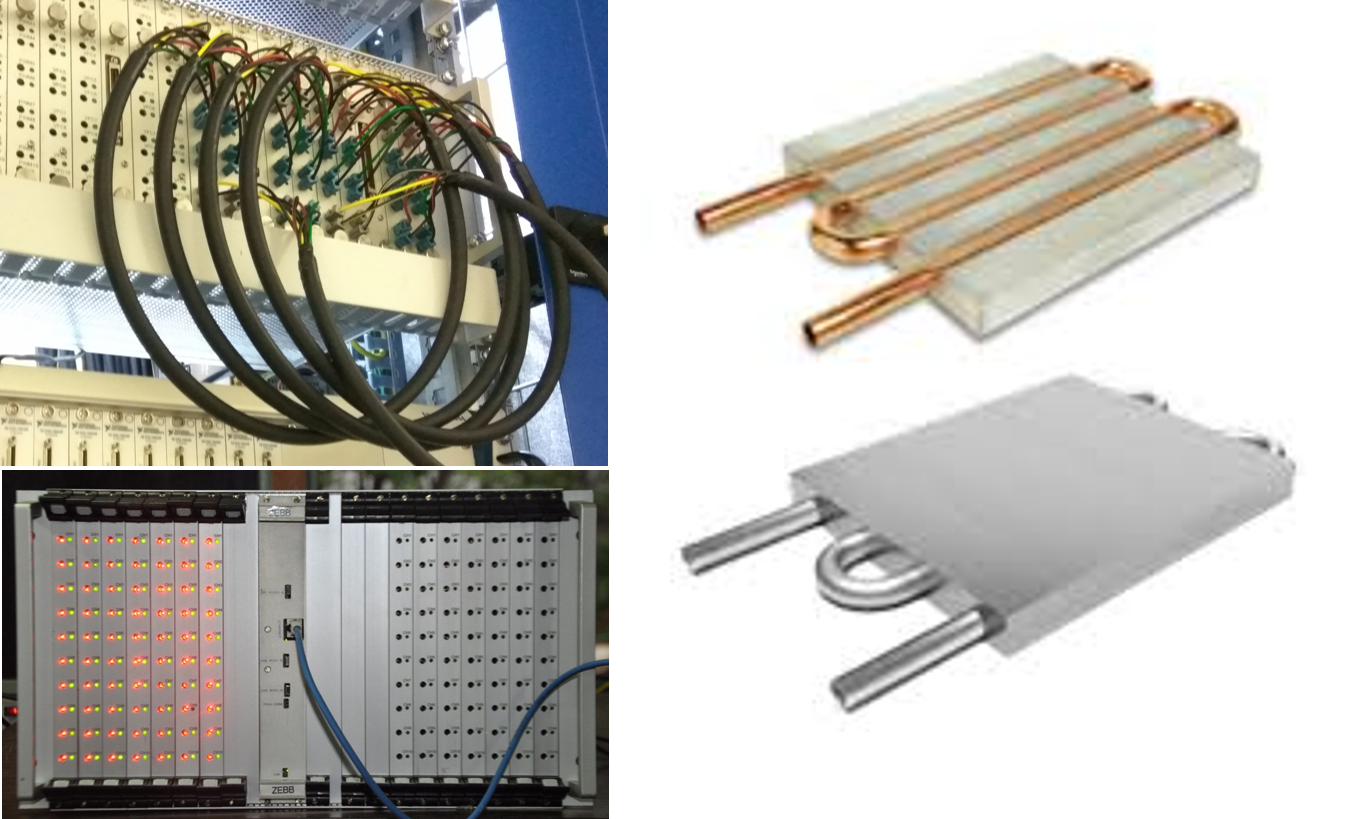

Improvements/Risk Mitigation

- Obsolesce management,

- Controller hardware

- Controller firmware

- Interface hardware

- Refinement of Operating modes and test scenarios

- Heatsink with SS tubing

Infrastructure facilities

- Equipment Layout mimicking IO site provisions

- 22kV Distribution system

- Dummy loads

- DM water facility

Industrial Participation

Partnership with Electronics Corporation of India Limited (ECIL) has enabled large-scale manufacturing with technology transfer success. ECIL completed Final Design Review (FDR) with Manufacturing Readiness Review (MRR) scheduled for March 2026. Current production includes 8 units of dual output ICPS and 4 units of ECPS for ITER France delivery.

Over two decades, ITER-India developed comprehensive vendor capabilities for high-performance components including multi-secondary transformers, SPS modules, and specialized measurement devices, all meeting stringent international standards (IEC 60038, NFC, Eurocode 8). Supporting ITER's 20-year lifecycle, systems utilize mostly COTS components.

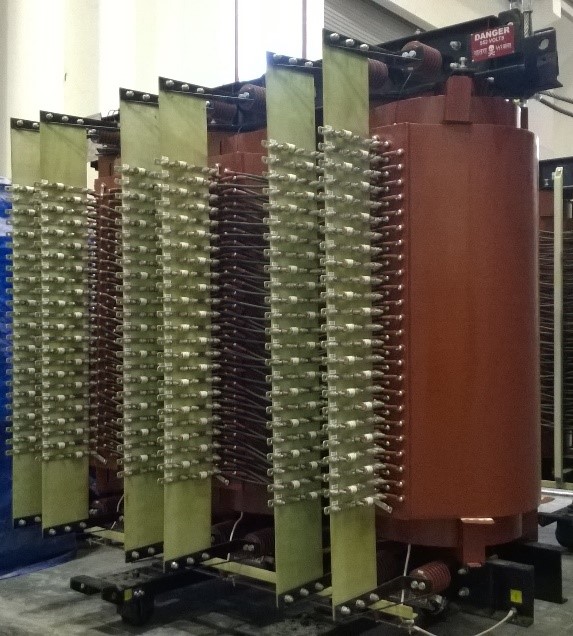

Multi-Secondary Cast Resin Transformers

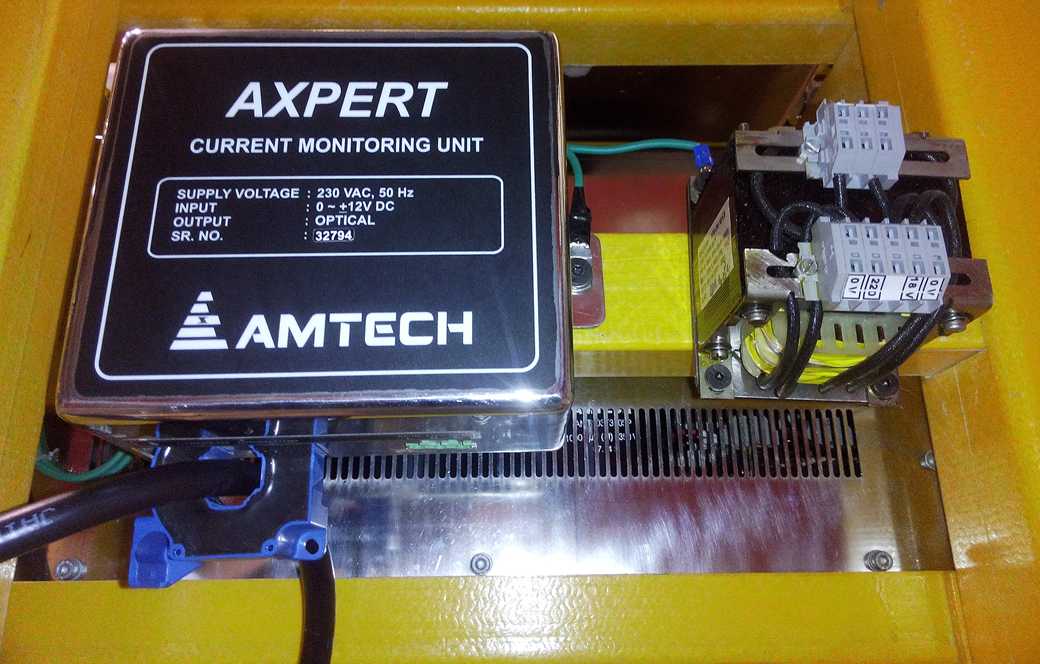

CURRENT MEASURING UNITS (CMU)

MULTI-SECONDARY OIL COOLED TRANSFORMERS

HIGH VOLTAGE WALL THROUGH BUSHING

Switched Power Supply Module for High Voltage PS

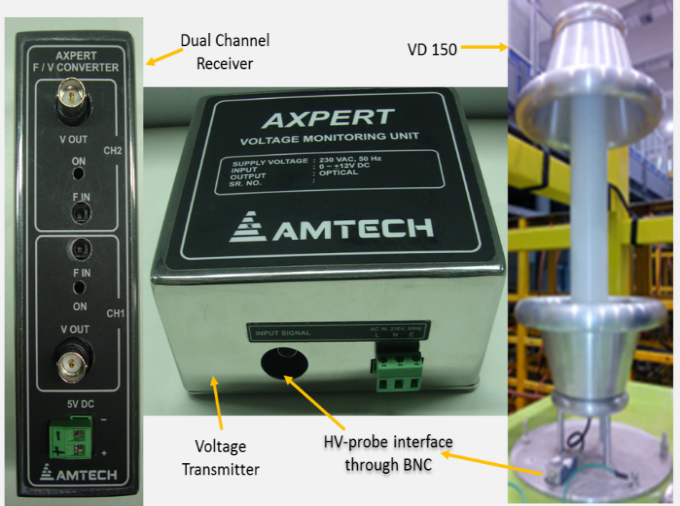

VOLTAGE MEASURING UNITS (VMU)

8kV, 480kW, FAST MODULATING POWER SUPPLY

Composite High Voltage Transmission Line for Electrical/RF power, hydraulic/gas feed