India’s contribution to ITER Cooling Water System enters commissioning phase

The heat generated in the ITER Tokamak along with the heat generated by auxiliary heating systems and supporting systems (approximately 1150 MW) will be transferred to the atmosphere with the help of Cooling Water System (CWS). The CWS consists of four sub-systems, viz. Tokamak Cooling Water System (TCWS), Component Cooling Water System (CCWS), Chilled Water System (CHWS) and Heat Rejection System (HRS). Among these sub-systems, the supply of CCWS, CHWS and HRS is part of India’s in-kind contribution to ITER project as one of the nine procurement packages.

The route from design to engineering, manufacturing, procurement and testing of the components and system as a whole followed the concept and functional specifications of the system provided by ITER organization. Most of the components and related sub-assemblies were manufactured in India across different locations and included the involvement of several contractors/ sub-contractors/ manufacturers. The design, manufacturing and testing of the supplied components followed the stringent quality norms of ITER nuclear establishment. All deliveries related to this procurement package were completed in 2021.

The equipment/ components delivered by ITER-India include cooling tower of 510 MW heat rejection capacity constructed of FRP structures with dimensions 80m (L) X 32m (W) X 20 m (H), plate type heat exchangers of capacity upto 70 MW each, water cooled chillers of 1200 TR each, pumps with flow rates upto 1.87 tonnes/sec each, electrical motors upto 1.4 MW capacity each, soft starters of 6.6 kV/ 800 kW capacity each, variable frequency drives of 6.6 kV/ 750 kW capacity each, E-house of size 21m (L) X 7m (W) X 4m (H), piping of ~16.5 km length with sizes upto 2m diameter - supplied as fabricated ~4500 spools involving one lakh inch-dia welding, 900 MT of piping supports, ozonators, 1400 nos. valves (different types and sizes), cables of ~61 km length, water polishing units, various instruments, stop log gates, bellows, pressurizers, panels, heat tracing components, etc.

Most of the equipment have been installed and commissioning activities are underway at ITER site to support the first plasma operation deadline of 2025.

For more details refer to https://www.iter.org/newsline/-/3720

|

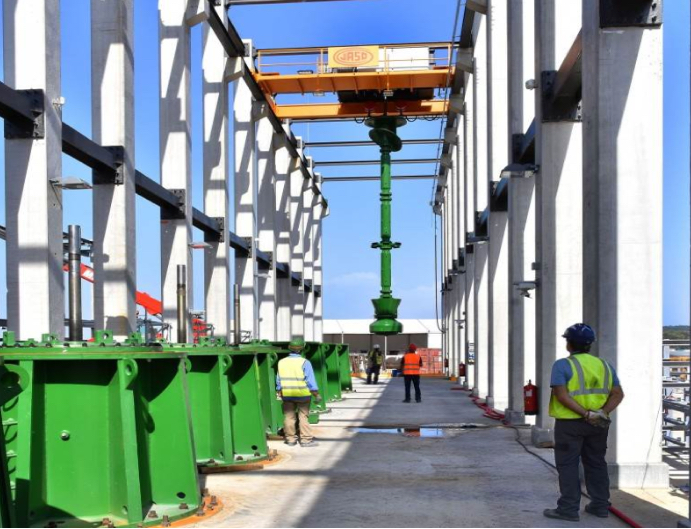

Vertical pumps during assembly at ITER site

|

|

Installed Cooling tower at ITER site

|

|

MCCs under energization

|

|

Installed piping at ITER site

|