“Make in India” Cryolines for ITER project

ITER (www.iter.org) is an international collaborative project to harness controlled nuclear fusion of Hydrogen isotopes to produce energy. It is an important step towards an alternative and virtually limitless source of clean energy. ITER-India (www.iter-india.org), part of the Institute for Plasma Research under the Dept. of Atomic Energy, is responsible for Indian contributions to the project. ITER employs a magnetic “cage” to contain the hot plasma. This cage makes use of superconducting magnets, which must be cooled to minus 269 deg-C, just 4 degrees above absolute zero. ITER will employ the biggest Cryoplant in the world coupled to a Nuclear Facility, and the liquid helium & nitrogen produced by this plant will be distributed to the magnets through a massive network of “cryolines”.

Approximately 4 km of Cryolines, operating at temperatures ranging from minus 269 to minus 193 deg-C, and about 6 km of return lines for warm gases, have been manufactured by M/s INOXCVA (www.inoxcva.com) in India and then dispatched to the ITER Worksite in France. The last consignment of these lines was flagged-off on 29th July’21 at M/s INOXCVA’s factory in Kalol Village near Vadodara in Gujarat.

These Cryolines are made to stringent Nuclear standards. These are ‘first of a kind systems’ in terms of large size (diameter upto 1 m), and include multiple process pipes with very low heat loss and complex layout. ITER-India and M/s INOXCVA established the design through meticulous prototyping and qualification before starting production. ITER-India, DAE and M/s INOXCVA are proud that India has demonstrated its ability to develop a hi-tech, first-of-a-kind product in Cryogenics, at par with the best in the world, a good illustration of Atmanirbhar Bharat.

The ceremony was remotely attended by Sh. K.N. Vyas, Secretary, DAE, Dr. Bernard Bigot, Director General of ITER Organization, Dr. Shashank Chaturvedi, Director, Institute for Plasma Research, and many others. Dr. Bigot applauded the engineering & manufacturing capabilities of INOXCVA and the quality and promptness of project related deliveries. Addressing the audience Sh. Vyas said, “I am happy to see M/s INOXCVA as one such industry which has made its presence felt globally in a short span of 5 years in cryogenic lines at 4K temperature level, and I congratulate them for this”.

Some photographs from the event are appended below:

Shri K N Vyas, Chairman DAE and Dr Bernard Bigot Director General ITER France addressing the audience remotely

Final shipment flagged off by the dignitaries at M/s INOXCVA, Vadodara on 29th July 2021

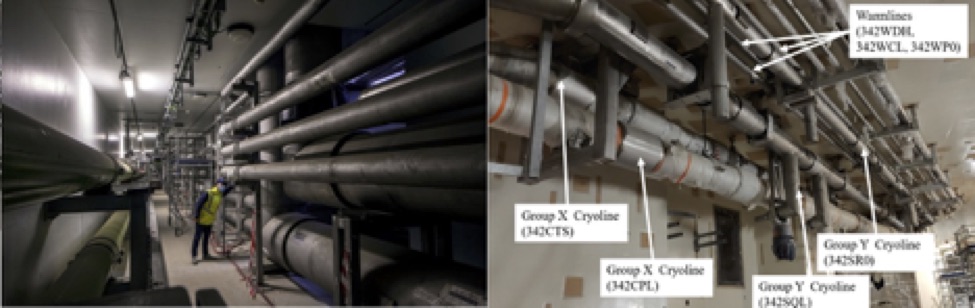

Some pictures of Cryolines manufactured in factory and installed at ITER are seen below:

Multi-process pipe cryoline under manufacturing and assembly at M/s INOXCVA , Vadodara

Cryolines and Warmlines manufactured by M/s INOXCVA under installation at ITER site